GENERAL

Why Indented PC Wire / Bar for Concrete Reinforcing?

In the pre-tensioned concrete application, the pre-stressed steel wire is tensioned approx. 70 to 80% of the minimum specified breaking load of steel wire prior to casting of concrete. After initial setting of concrete, the pre-tensioned steel wire is released and the stress in the wire is induced in the concrete. This induced compressive stress will neutralize the tensile stress caused by the acting loads on the concrete member. In the case of pre-tensioning, it is important that adequate bond is created between the steel wire / bar and concrete in order to transfer the desired compressive force from the steel wire to the concrete.

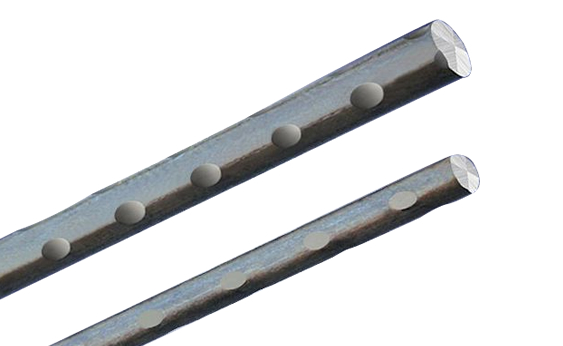

In order to improve the bond strength and achieve a consistently low transmission length, regular indentations of specified shape in the wire / bar surface is introduced. Slotted in opposite or 120-degree planes or 90-degree planes.

How to get Steel Wire / Rod Indented?

In the known art of indenting operation, it is possible only to make 2, 3 or 4-sided intermittent indentation on the surface of the wire. This indentation is normally carried out on a wire-drawing machine and is effected by pulling the wire through appropriate indenting rolls.

Advantages of Indented PC Wire

- Improves the bond strength between pre-stressed steel wire and concrete

- Reduces the frictional losses between pre-stressed wire and concrete

- Increases the anchorage efficiency

- Maintains higher effective pre-stressing force in the structure

- Reduces the number of operations at the customer end

Technical Data Tensile Strength, Extension Stress, Elongation, Relaxation Value References for Indenting PC Steel Wires

| Nominal diameter (mm) |

Tensile strength No less Than (MPa) |

Off-proportion extension stress no less than (kN) |

Elongation no less than L0=200mm (%) |

Bending test | Relaxation Value 1000h no more than |

||

| Times/ 180° No less than |

radius (mm) |

Ⅰ | Ⅱ | ||||

| ≤5.00 |

1470 1570 |

1250 1330 |

3.5 | 3 | 15 | 8 | 2.5 |

| >5.00 |

1470 1570 |

1250 1340 |

|||||

Standard Followed

MS, JISG, ASTM, BS, other int'l standards.

SPECIFIC PRODUCTS

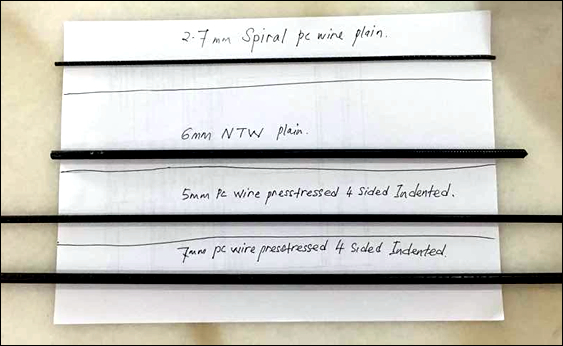

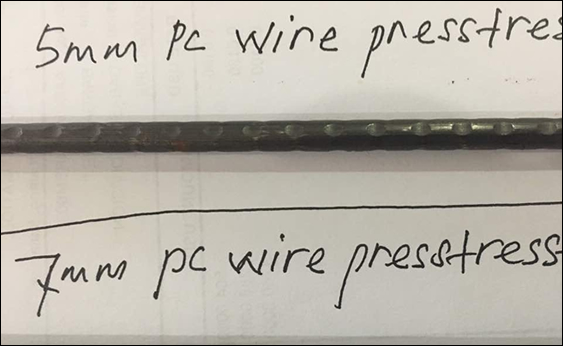

Prestressed PC Wire- 4 side indented oval shave

OD 5mm

OD 7mm

Wires exported to Malaysia

PC Wire 4 Side Oval Indented made with from cold drawn wire according to Maylasia International Standard MS1138

Straightened indented cold drawn pre-stressed steel wires - 3 side indenting

7mm, ASTM A881-10, 250k indented mono wire with

3-sided intermittent indentation on the surface

Wires exported to Syria

Steel wires of nominal diameter 7 mm.

Quality:

according to the EN 10138/4/979 or BS 5896/80

-Nominal tensile strength: 1570 N/mm2

-Yield limit : 1420 N/mm2

-Guaranteed Yield point: at 0.2 % of permanent elongation 1380 N/mm2.

-Deflections : Max. 12 mm in 1 meter long.

-Diameter tolerance : 7 mm ± 0.05 mm

-Relaxation: Class 1 or Class 2

-Weight of Coil : manufacturer Choice , preferable less than 1000 Kg .

-Coil nominal inner diameter: 1800-2000 mm.

-Coil nominal outer diameter: about 2200 mm.

-Indentation depth: 0.15 mm± 0.05 mm , three indented faces with angle 45° , pitch 8 mm.

PC Single Wire - Normal Relaxation 4 Phase Indented

PC wire for prestressed concrete electric pole and concrete pile applications.

Specification per SNI(standard National Indonesia) or GISG3536.

Wire diameter: 7.0 mm

Surface: Smooth and indented with groove

Wires exported to Indonesia

Pre-stressed Concrete Wire, 3 Side Deformed

Wires exported to Brazil, with specification details below:

Diameter: 5.00 mm slotted - ( 3 sided Deformed – Chevron)

Nominal sectional area: 19.6 mm2

Strength: 1770 MPa

Mass of the section: 153.1 g / m (+2%, -2%)

Maximum Cargo of Rupture: 36.5 KN

Specification: CP-175 RB 5 / ASTM A421-91/ABNT NBR 7483

Diameter: 4.00 mm slotted - 3 faces ( 3 sided Deformed – Chevron)

Nominal sectional area: 12.6 mm2

Strength: 1770 MPa

Mass section: 98.4 g / m

Maximum Cargo of Rupture: 25.6 KN

Specification: CP - 175 RB 4 / ASTM A421-91/ABNT NBR 7483

Diameter: 6.00 mm slotted - 3 faces (3 sided Deformed – Chevron)

Nominal sectional area: 28.3 mm2

Strength: 1770 MPa

Masa Section: 221 g / m

Max.Carga of Rupture: 57.6 KN

Specification: CP - 175 RB 6 / ASTM A421-91/ABNT NBR 7483

PC Wire Chevron 4 Sided Indented

Wires exported to Philipines

Product : PC Wire 4 Sided Indented

Size

5mm

6mm

7mm

9mm

We also export PC Wire INDENTED, 5mm and 7mm, packed in 1-2 tons coils to England.